SHAPE

MATTER

#MakeTogether

Our diversified expertise in the screw-cutting industry extends over several production sites with consequent, modern means of production adapted to the requirements of our customers, giving us a powerful industrial strike force. Machining from Ø0,4mm diameter to Ø240mm diameter

Our 8 specialized businesses enable us as a Group to cover all market types in order to be present in a wide range of business sectors.

-

Automotive

-

Buildings

-

Connectic/Electronic

-

Industrial Equipments

-

Medical

-

Trucks

-

Sport & Leisures

-

Agricultural

-

Luxury & Cosmetic

-

E-Mobility

-

Aeronautic/Aerospace

-

Energy

-

Defense

Our varied methods of production enable us to cover and master all precision machining techniques and particularities across all sectors.

Cam Multispindle

Stemming from conventional undercutting, multi-spindle lathes give you very high productivity, thanks to simultaneous machining of several parts.

It thus particularly suits large series such as those found in the automotive field for example.

#Competitivity #Simple design

CNC Single-spindle lathes

The CNC single spindle lathe provides a wide range of possibilities, enabling us to handle all your projects…

#From prototype to large series #Flexibility

CNC Multispindle

The productivity of conventional multi-spindle lathes combined with the possibilities of CNC.

The CNC multi-spindle lathe is capable of complex processing (milling, transversal drilling, etc.) in the most demanding materials

#Productivity #Complex parts

Escomatic

The Escomatic machines are specifically designed for simple and complex parts, with machining diameters from 0.4 mm to 6.5 mm.

Suitable for the production of large series, they offer the advantages of CNC machining for the production of small, medium and large series with the economic advantages of the Escomatic technology.

#Very high productivity #Small diameter parts

Transfert Machine

The transfer machines allow us to carry out several processes from blank (turning, casting, cold heading).

The simultaneous processing of several parts means that we can reach a high level of productivity and competitiveness, even when designing complex parts.

#Dedicated to one project #Complex design

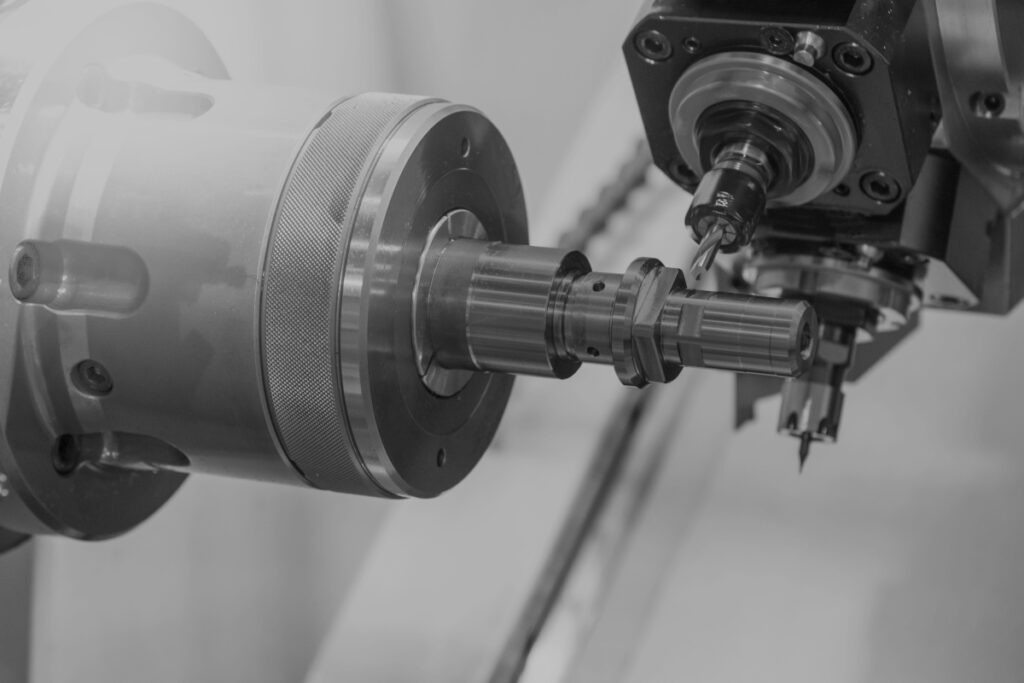

Grinding

Grinding is a finishing operation that is carried out after machining that achieves great dimensional and geometric accuracy as well as a fine surface finish.

Grinding is used especially for shafts mounted with bearings and seals.

#Dimensional and geometric accuracy

#StrongerTogether

CONTACT

Phone : +33 (0)4 50 78 29 87

Email :commercial@ekaim.fr

ADRESS

370 Avenue des Jourdies

Entrée A2, 2ème étage

74800 SAINT-PIERRE EN FAUCIGNY

FRANCE